Stainless Steel

What is stainless steel? Stainless steel contains a minimum of 12% chrome, added during the manufacturing process to its main constituent - iron. The Chrome gives it its 'stain less' property, with the beauty of not being a coating that once damaged renders the material susceptible to corrosion. If stainless surface is damaged, in the right environment, it will heal. This is ideal in industrial applications where the loss of a coating would have meant that the product could suffer premature failure.

What is stainless steel? Stainless steel contains a minimum of 12% chrome, added during the manufacturing process to its main constituent - iron. The Chrome gives it its 'stain less' property, with the beauty of not being a coating that once damaged renders the material susceptible to corrosion. If stainless surface is damaged, in the right environment, it will heal. This is ideal in industrial applications where the loss of a coating would have meant that the product could suffer premature failure.

There are different grades of stainless steel, each type is specifically suited to specific applications. For instance, the Ferritic Grades of stainless steel are predominantly Chrome containing, with an an increase in chrome giving greater resistance, to amongst other things, corrosion resistance. Grade 430 is one of the more popular grades of ferritic stainless steel.

The austenitic range of stainless steels contain nickel as well. This changes the physical and mechanical properties to non-magnetic when fully annealed, with improved formability properties. Additional alloying elements are used for specific grades, such as sulphur improve machinability, or Molybdenum, giving even extra pitting resistance. The more popular austenitic grades are 304 and 316 stainless steel.

Beyond this, there are the Martensitic grades of stainless steels, used for knife blades due to their hardness, Precipitation hardening grades, which harden after quench tempering, as well as the Duplex range of stainless steels.

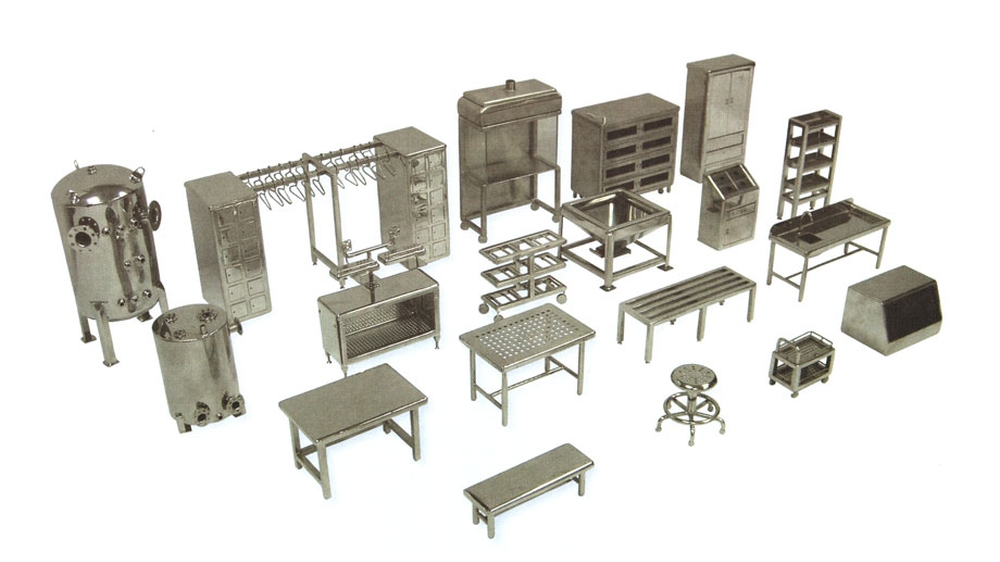

As mentioned above, all types and grades of stainless steels have their own unique uses and applications. Feel free to drop us a line to learn more about the best option for your specific requirement.

A corrosion resisting steel was developed in the late 60's to assist in applications where the ferritic grades could not - thicker applications that required welding. The material is called 3CR12 and is used widely amongst mines where wet abrasion required additional corrosion protection.

A corrosion resisting steel was developed in the late 60's to assist in applications where the ferritic grades could not - thicker applications that required welding. The material is called 3CR12 and is used widely amongst mines where wet abrasion required additional corrosion protection.

3CR12 is also used as a general utility steel, both in coated and uncoated applications. Example of its endurance is the above 3CR12 braai after 20 years uses near the coast.

If you would like to know more about this product, feel free to drop us a line.